As an essential lighting tool for everyday lighting, camping, and emergency. The aluminum flashlight is a popular product in supermarkets, auto inspection, promotional and hand tools. Over the years, more and more Amazon sellers have added LED flashlight to their shop.

As a buyer, if you find a suitable flashlight supplier. And with the initiative and get a reliable price when negotiations. As an over 9 years experience had touched with a variety of buyer. The key reason has the initiative is that let the supplier know that you are a specialist in the flashlight.

If you want to become an expert on flashlights in shortly. You must lean the aluminum LED flashlight production process. And know the core components of costs and technologies.

Now we talk about the simple of the core technologies and cost.

Aluminum LED flashlight core technologies and cost is PCB, LED chip and structure.

PCB:Generally, We Distinguish A PCB Quality Could Via 3 Ways Of The Surface

1- From the PCB thickness; The different PCB material with different quality and cost. The PCB more thickness its high-temperature resistance is better. And resistant to deformation.

2- From the PCB gloss and color; PCB surface must with a layer printing ink. The printing ink as an insulation function. If its surface does not gloss enough and lack of printing ink, it will easy heating, short circuit, and open circuit. then the PCB quality will have influence in using.

The PCBA welding appearance. Because of a PCBA with many components. If the welding not stable, then the components will easily fall off. It will influence quality seriously.

A Good Quality PCB Need To Met Below Requirement

1- The component easy assembly and could fix well.

2- The circuit’s width, thickness, and spacing shall meet the requirements to avoid heating, circuit breaking and short circuit;

3- In high temperature, the copper does not come off easily.

4- The copper surface is not easy to oxidize, which affects the installation speed. And the copper is broken after oxidize.

5- No additional electromagnetic radiation.

6- Shape is not deformed, so as to avoid deformation of the shell after installation, screw hole dislocation. Now are mechanized installation, circuit board hole position and circuit and design deformation error should be within the allowable range.

7-High temperature, high humidity, and special environment resistance should also be considered.

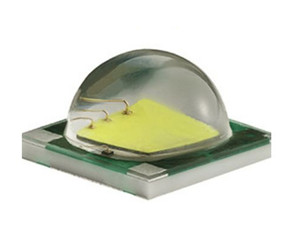

Regard LED Chip; Aluminum led flashlight normal use 3 kinds LED chip, such as common LED, CREE LED and OSRAM LED.

LED chip: common LED,Cree led and OSRAM LED.

Common LED: It is easy to assess the cost, the different led quantity the price different. Also, the LED color also will influence the price.

Cree LED: Its different series chip with different price and lumens.

OSRAM LED: Because of its price high and bright similar to CREE. So it is not usually to use on the led flashlight. Expect the client’s special requirement.

The Cree LED;(Most popular using high power led flashlight) ;

Cree LED has many series; Different series with different feature.

Please find below the date from CREE Official.

The Cree XPE chip theoretical value max could reach 122Lumens/W.

The CREE T6 chip theoretical value max could reach 170Lumens/W.

But in actual production according to the different battery power, the CREE LED mini is 80Lumens/W.

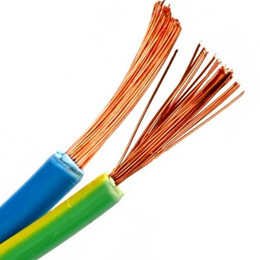

About Cable: To judge the quality of a cable is to testing.

Take a wire head to bend repeatedly. If the cable soft, good fatigue strength and there is no crack on the wire insulator is a superior product.

Cut out a length of cable to check the copper cable is located in the middle of the insulation layer or not. If not, the thinner side will be punctured by the current.

Checking the copper: The high-quality copper cable should be amaranth, glossy and soft. And inferior of copper cable the color purplish black, yellow or white with poor toughness. Easy be a break.

Battery: For Aluminum LED Flashlight most use AA Battery, AAA Battery, 18650 Li Battery, 14500 Li Battery.

AA & AAA battery with 2 versions: carbon battery and alkaline battery. Normally alkaline battery price is higher than carbon battery.

Dry battery (AA battery & AAA battery) brands: Duracell battery & ENERGIZER battery & RAYOVAC battery.

18650 Li Battery and 14500 Li Battery: The rechargeable battery price is according to its capacity. Such as 1200Mah, 1800Mah, 2000Mah, 2400Mah.

The structure of LED Flashlight; From weight, components and surface grain complexity three parts to analyze.

Weight: It is easy understanding. The flashlight heavier it uses more material. So the price is higher.

Components: If a flashlight with too many components, it means need more production processes. So the labor cost and material wastage will be added. The price will higher.

Surface grain complexity: The grain more complexity is more hardly production. During production, the labor cost and material wastage will increase. So the price will increase.

But the high power led flashlight also have an important part easy to ignore. It is a reflector. Commonly use 2 types reflector glazed surface and orange peel grain surface.

Glazed surface reflector, the light is very concentrated, can reflect a more perfect spot through the reflector, suitable for remote lightings, such as hunting, adventure.

Orange peel metal reflector with good floodlight effect, diffuse reflection, wide and clear irradiation range, used for close lighting.

Also, the reflector’s material could be metal and plastic. The metal reflector with better heat dispersion. This is very important for high power flashlight. But its weakness is a high price than a plastic reflector.

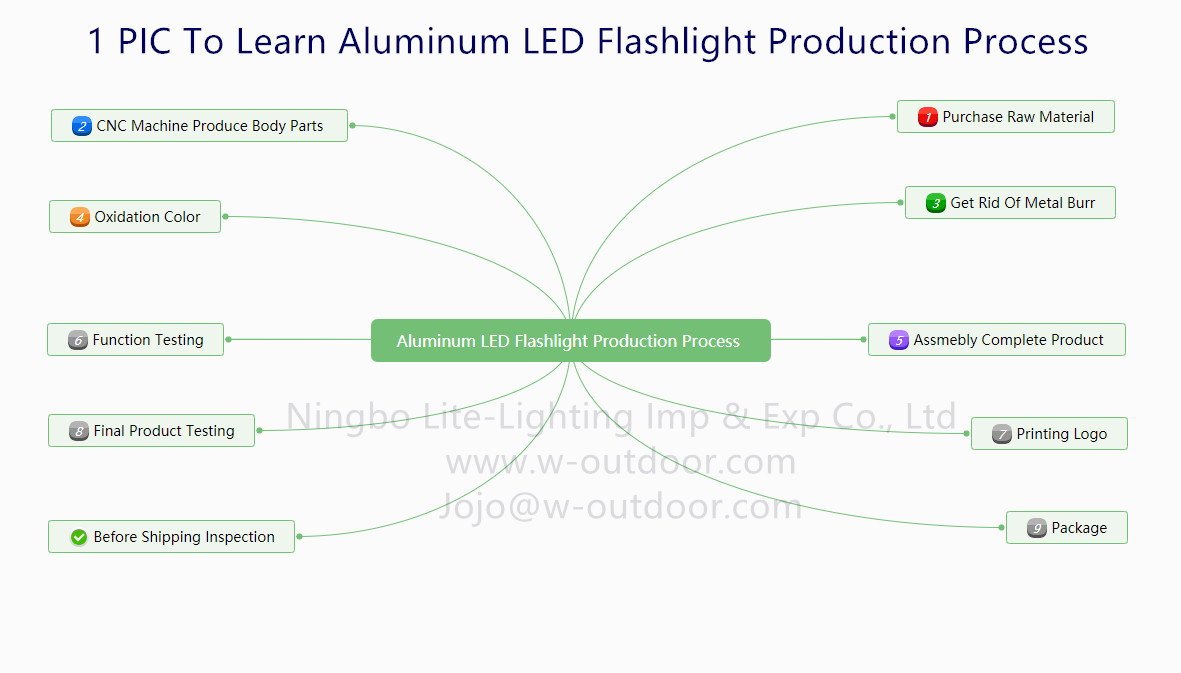

After finishing the core technology and cost analyzed. Now use 1 picture to know the aluminum flashlight manufacturer production process

1-Purchase raw material:

Include Aluminum, LED chip, switch, O ring, Lens, spring and other spare parts.

Aluminum:

Aluminum Advantage: High strength, good heat dissipation, and can withstand high temperature without deformation, can use CNC manufacturing to make a complex structure. The surface anodizing treatment can get good wear resistance and easily customized color.

LED Chip:

All LED need to testing and screening in the procurement process. The same batch of the LED must with same color temperature.

Switch

There is 3 kind switch on the flashlight . Mouse tail switch, button switch, and light touch switch.

Mouse tail switches normal use for the gun.

Button switch is most use in a led flashlight. The switch quality directly affects the flashlight lifetime.

Touch Switch: Most uses on high power led flashlight and looks with high class. But its weakness is some time unstuck.

O-ring is made of silica gel. A suitable size O-ring could improve the flashlight waterproof level, also the O-ring is an essential part of a flashlight.

Lens: The material of the lens is divided into glass and resin. The glass material has better light transmittance and is heavier. Resin lenses are lighter and less permeable than glass lenses.

Springs and other accessories are available in different sizes. The difference is a few.

LED Flashlight Shell Production

A flashlight shell design must consider the overall structure and function. If you want a flashlight with good heat dissipation performance and waterproof. It needs a scientific structure design and accurate CNC process. Each component production should accurate to 0.01 mm. In this way could get is a compact flashlight.

After CNC process, the flashlight aluminum shell will have some metal burr. Because of the metal burr is tough and easy hurt labor. So before proceeding to the next production step. We must get rid of metal burr firstly.

Get Rid Of Metal Burr

Oxidation Color

Any aluminum product must through oxidation to dye. The oxidation color has 2 different types. Hard Oxidation & Common oxidation. Compare the hard oxidation with common oxidation, the hard oxidation more thickness, and more rigidity. For example, common oxidation thickness is 8-12um, the hard oxidation is 40-70um. And common oxidation rigidity is HV250-350, the hard oxidation rigidity is HV350-550. Also, the hard oxidation with better insulation, wear resistance, corrosion resistance than common oxidation. As a result, the hard oxidation cost is higher than the common oxidation.

During oxidation color, A flashlight different parts with different shape and thickness. Because of the oxidation color, each part is separate. In order to ensure a whole flashlight with the same color. Then it will need a technician setting customized oxidation time according to the shape and thickness.

All aluminum flashlight color could be customized according to Pantone No…

In brief, This production is welding LED and components in PCB. And assembly the PCBA, reflector, spring, switch, O-ring and aluminum to a complete flashlight. In this step, the most important is all components must in its position with a complex and rosin joint.

Flashlight Assembly

Function Testing

Each flashlight must pass 3 times strict testing. This the firstly testing is inspection the flashlight’s function, led chip lighting and switch working.

Once a flashlight to this step, it means the flashlight had passed the first testing. Aluminum flashlight logo printing could use silk-screen printing and laser printing. Silk-screen printing is multicolor from 1 color to 4 colors LOGO printing. But silk-screen printing on aluminum is easy to fall off.

Laser printing is most often use in aluminum products because it easy operates and firms on the surface. But its weakness is color singleness. All laser printing logo color is aluminum material color.

Printing LOGO

Besides the simple LOGO printing. Flashlight surface also could via thermal transfer printing or Hydro-transfer printing to realized some complex design printing. Such as camouflage, carton image and so on.

Finish Products Testing

Because all testing is manually operated, in order to avoid the labor works fault. We will arrange finish products testing with other workers. This testing is focused on led flashlight function and appearance, LOGO printing, package material checking.

LED flashlight package normal have display box, color box, double blister package, slide package, Sandwich package, and gift box. Some of the clients will put some accessories in the package, such as manual and bags.

Package

Pre-delivery Inspection

As before 2 testings is 100%, the pre-delivery inspection is spot check. We are strictly according to AQL1.5-2.5 standard.

If you are sourcing LED Flashlight or had sell LED Flashlight already. Contact with us now to apply for FREE SAMPLE!!!!